Refineries

Distillation of crude oil with LEWA pumps, systems and plants

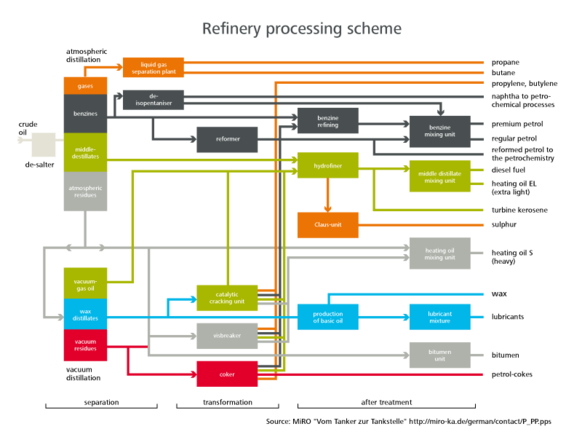

Crude oil has to be cleaned, separated, and converted (refined) until the final products suitable for sale are made. These include gas, diesel, heating oil, lubricants, propane, and butane.

These processes often involve complex distillation processes that require precision and reliability. LEWA supports refineries worldwide in various processes, which means that not only is it able to draw on a wealth of expertise, but also on a network of consultants and technicians, who support you on site when installing and operating your distillation plant.

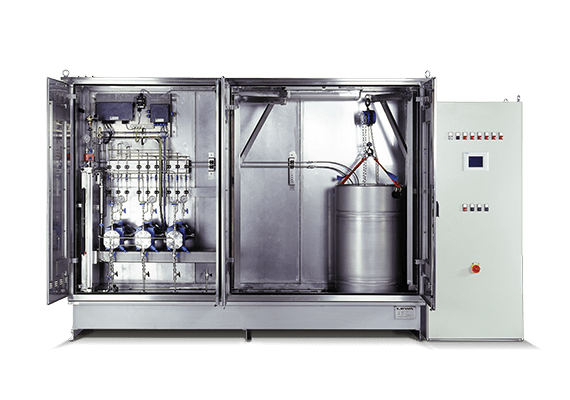

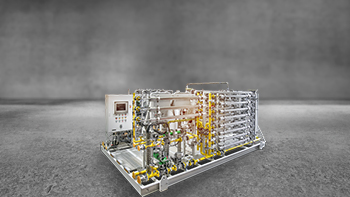

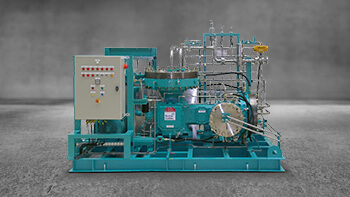

Our tried-and-tested pumps are used in various metering systems, which we build to meet your requirements and commission on your site.

Areas of application in crude oil distillation

Whether extracting crude oil or refining it further – LEWA products and systems offer solutions for all processes involved in the processing and refining of crude oil.

The diagram shows all the important refining processes. LEWA delivers fully customized plants and systems for almost all of them. Just ask our experts for more information!

| Product applications | Chemical | Process/System |

|---|---|---|

Metering of chemicals in refinery processes such as separation/destillation, transformation/conversion and finishing/refining | Amine solution | Distillation plant |

| Deposit inhibitor | Distillation plant, reformer system, cracker, coker | |

| Tetrachloroethylene | Reformer system, cracker | |

| Defoamer | Distillation plant, reformer system, cracker, coker | |

| Emulsion breaker | Desalination plant, distillation plant | |

| Corrosion inhibitor | Distillation plant, reformer system, cracker | |

| Metal deactivator | Cracker | |

| Caustic soda (NaOH) | Distillation plant, reformer system | |

| Sulfiding agent | Reformer system, cracker | |

| Water | Distillation plant, reformer system | |

| Antistatic additive, static inhibitor | Filling plant | |

| Lubricity improver | Reformer system | |

| Pour-point depressant | Distillation plant | |

| Colorants, marking agents | Filling plant | |

| Lubricity improver | Filling plant | |

| Octane booster | Reformer system | |

| Oxygen scavenger, oxygen binder | Cracker | |

| Hydrogen sulfide scavenger | Desulfurization | |

| Stabilizer | Catalytic reforming | |

| Wax dispersion agent | Vacuum distillation |

Advantages at a Glance

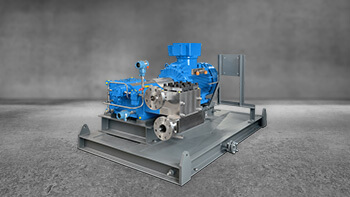

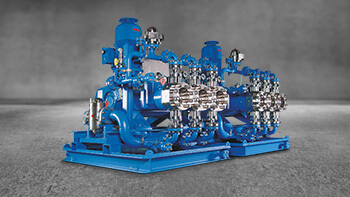

High end pumps, equipment and systems

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.

Spare parts information in your language

You will get all available information about spare parts (including subcontractors) in your preferred language. Our spare parts service functions quickly and smoothly.

-

- Sales Office Poland

- LEWA NIKKISO Austria GmbH (Sp. z o.o.) Oddział w Polsce

- +48 22 6358-204

-

info@lewa.pl